Liquid Density Meters for Fluid Concentration

The Bopp & Reuther DIMF Series of liquid density meters set the world standard for accuracy at a wide range of temperatures and process environments – including critical applications. Their low installation costs and little to no maintenance make them an ideal choice.

The Bopp & Reuther DIMF Series of liquid density meters set the world standard for accuracy at a wide range of temperatures and process environments – including critical applications. Their low installation costs and little to no maintenance make them an ideal choice.

Series DIMF 1.3

Non-aggressive liquids or liquid mixtures, hydrocarbons

Non-aggressive liquids or liquid mixtures, hydrocarbons

Accuracy: better than ± 0.01 %

Repeatability: better than ± 0.005 %

Series DIMF 2.0

Highly aggressive liquids, pastes, and foams. High flow rate design available

Highly aggressive liquids, pastes, and foams. High flow rate design available

Accuracy: better than ± 0.02 %

Repeatability: better than ± 0.005 %

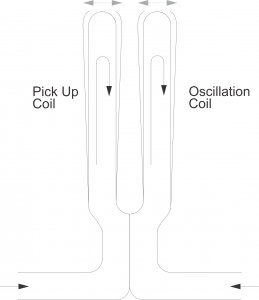

Liquid Density Meters – Operating Principle

The central sensor component of our density meters is an oscillation element consisting of an oscillation fork or tube. Flowing liquid passes through the oscillation element which is then electromagnetically excited and oscillates at its characteristic frequency. Changes in density result in changes in the characteristic frequency. These frequency changes are very accurately measured and registered directly by the transmitter.

Liquid Density Meters – Construction

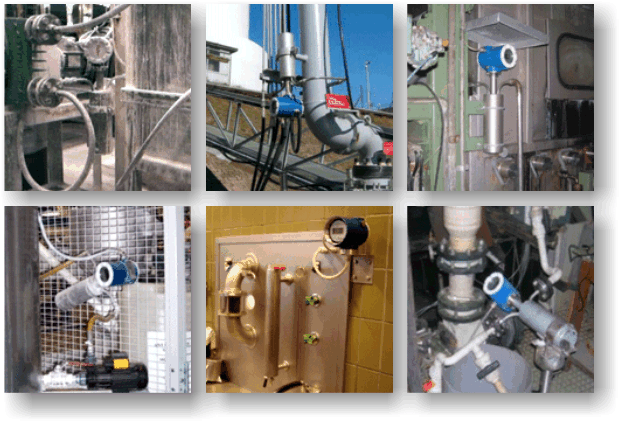

Depending on the corrosive or non-corrosive properties of the fluid you want to measure, these meters are constructed with robust and structurally sound stainless steel, hastelloy, titanium, or tantalum. They operate within caustic environments in many industries.

Liquid Density Meters – Applications

Hydrochloric Acid (HCL), Sodium Hydroxide, and chemical mixtures

Urea and water mixtures for fertilizer

Beer Wort

Viscose specialty fiber solvents

Ammonia water for textiles

Glycol concentrations

Methanol

Fuel and biofuels

Hygiene and cleaning products

Water and starch suspensions for paper

Detection of air bubbles in a pressure rig

Concentration of sulfuric acid in the copper industry

Harsh glue environments

Sugar solutions

Fat concentration in milk

…and many more.

Full Specifications Sheet – Liquid Density Meters DIMF Series – PDF

Contact Us (For more information or a quote)